Mega

By combining a wide know-how with the latest technology, MEGA Technical Team Unit is steadily committed to optimizing products and developing new projects.

ISO Standard bearings T2 Segment

We constantly improve and update different aspects of our standard bearings, such as materials, internal micro-geometry, general tribology, design of the parts and all other technical issues that may lead to increased bearing service life, thus reducing costs and allowing higher performances.

Technological bearings T3 Segment and AOB

We develop tailor-made solutions according to customers' evolving requirements. From pre-sales service to mass production you can get full support from MEGA.

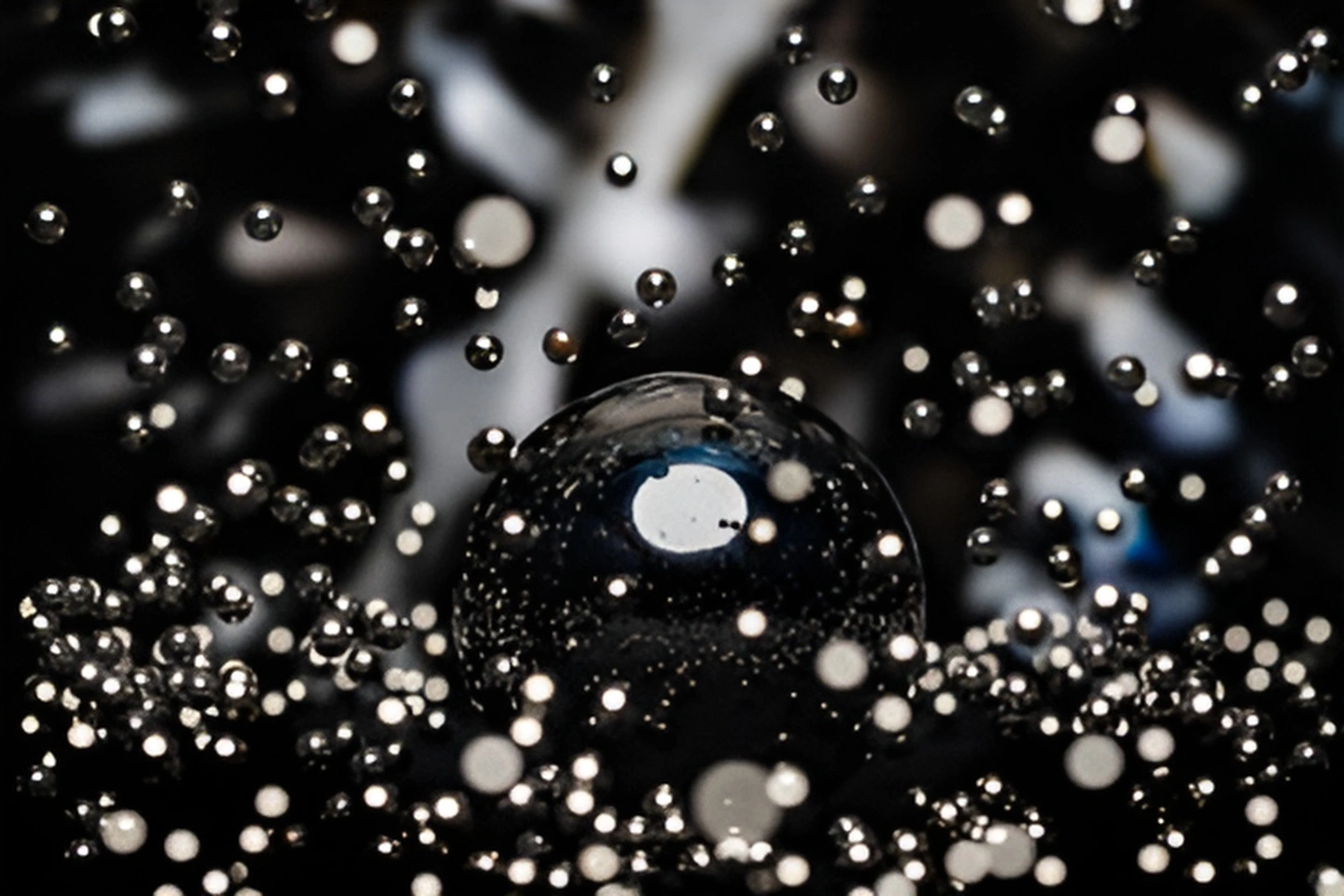

Counterfeiting rolling bearings is an illegal and unethical practice that could endanger operations and human lives! In addition, when you pay for premium high-performance bearings, but you get only poor faulty products, you get cheated!

Even skilled and experienced technicians may find it difficult to tell the difference between genuine and fake bearings without the appropriate tools.

We Mega provide full support to our users to get knowledge the quality which they are getting and the cost which they are paying. bearing dimensional and form compliance (diameters, lengths, roundness, cilindricity etc.)

bearing surface quality analysis (roughness, profile etc.)

bearing raw material metallurgy and metallography controls (chemical composition, microstructure, non-metallic inclusions etc.)

bearing mechanical properties assessment (hardness, case layer depth etc.)

full bearing root cause failure analysis